American Metal Spinning

The Manufacturing Process

We use a wide variety of processes to create specific shapes from specific materials. Also, producing custom designs based on your specifications.

We use a wide variety of processes to create specific shapes from specific materials. Also, producing custom designs based on your specifications.

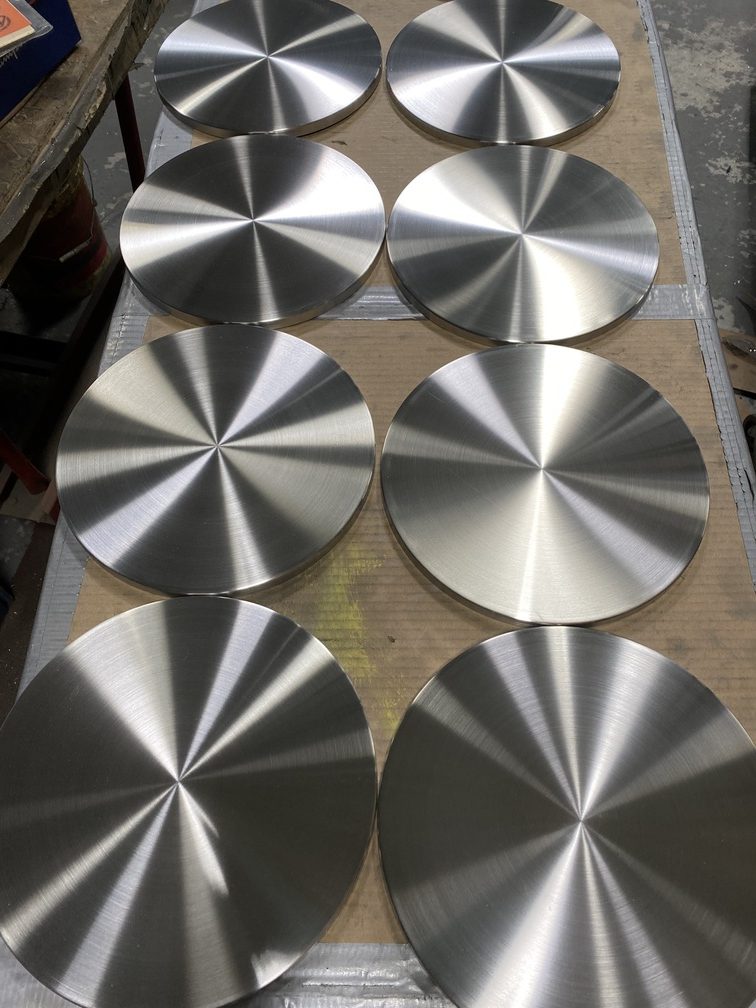

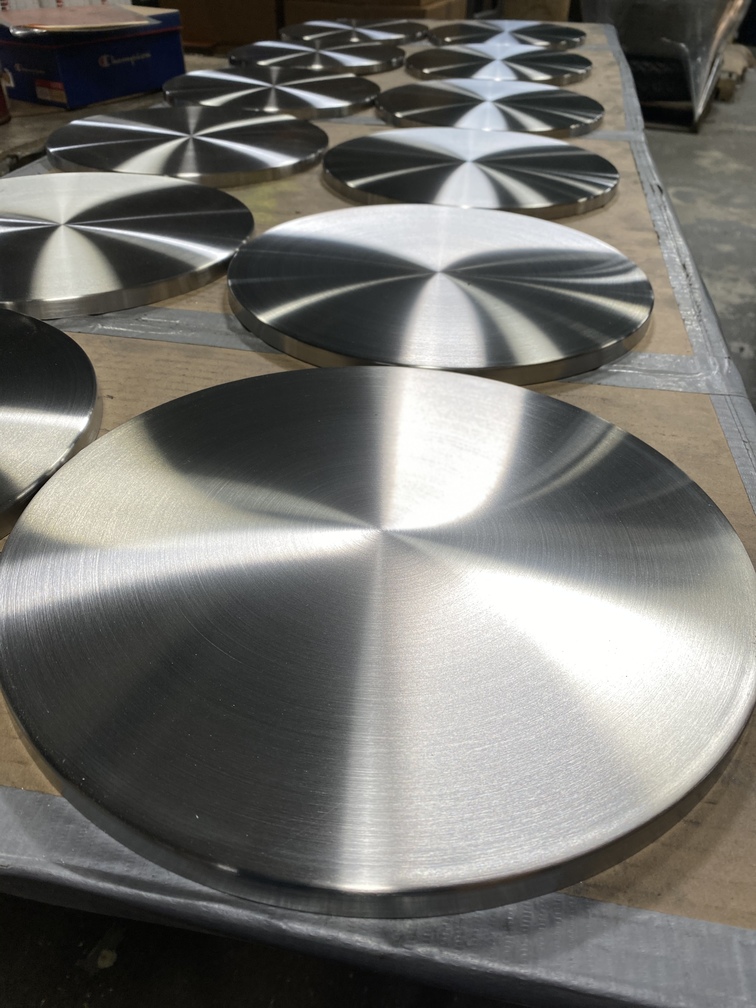

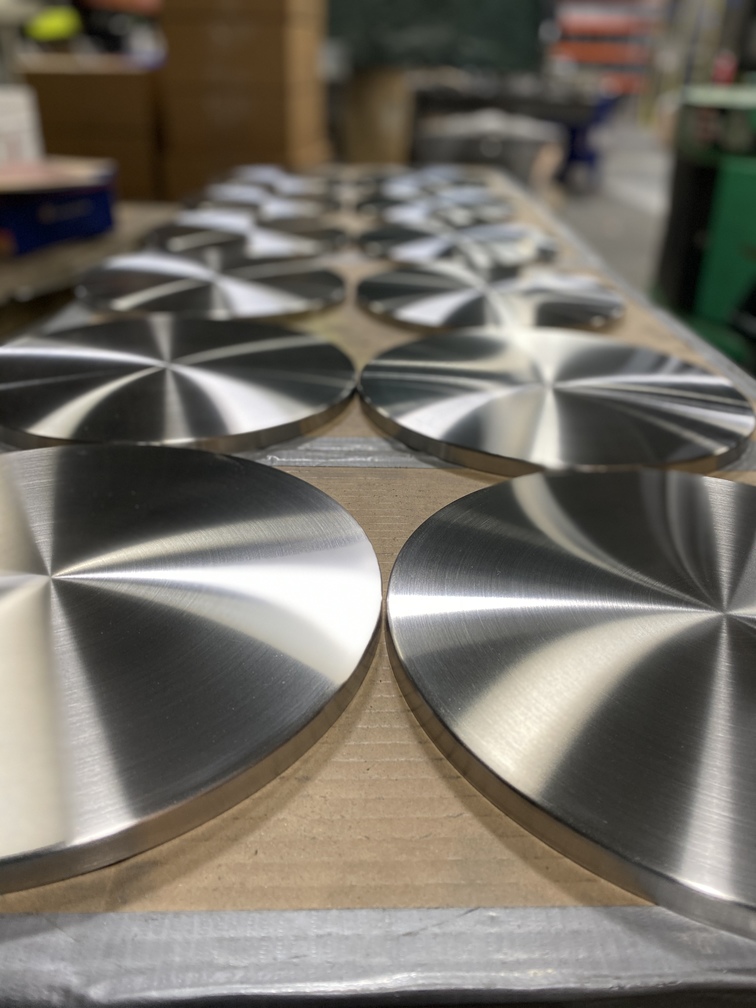

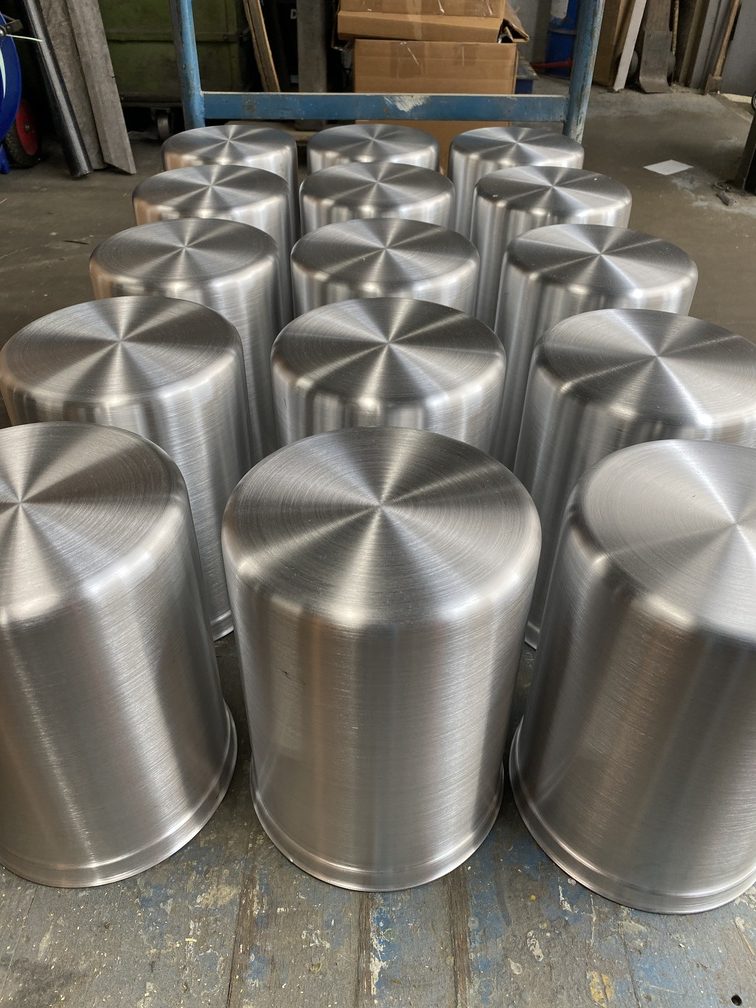

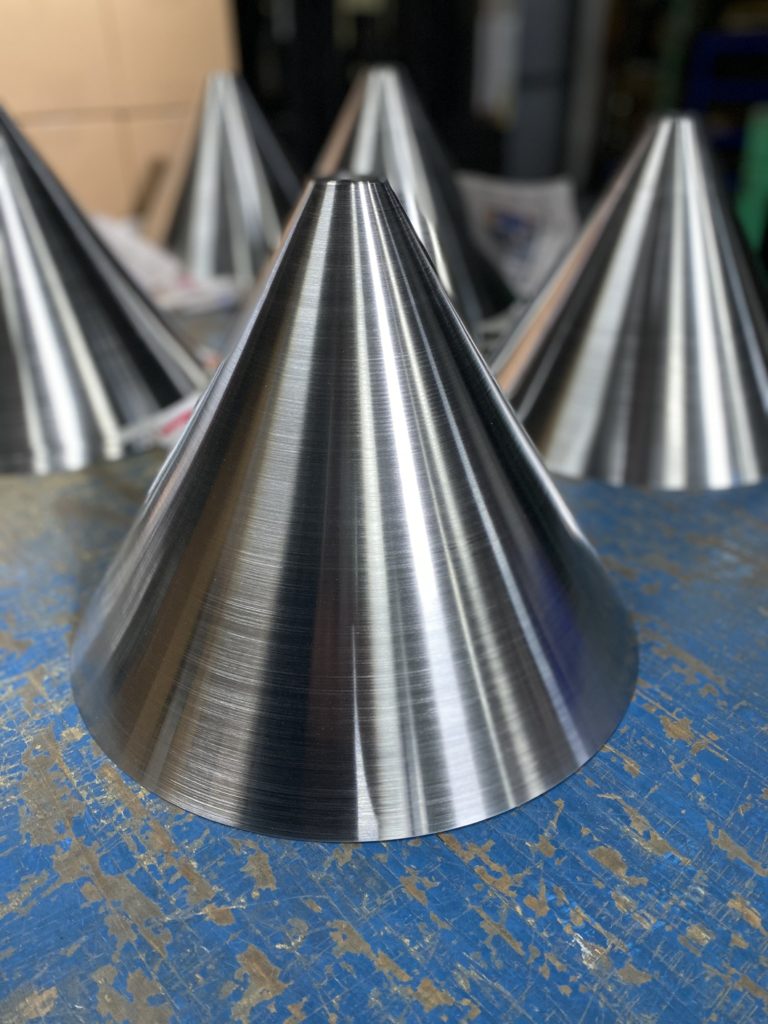

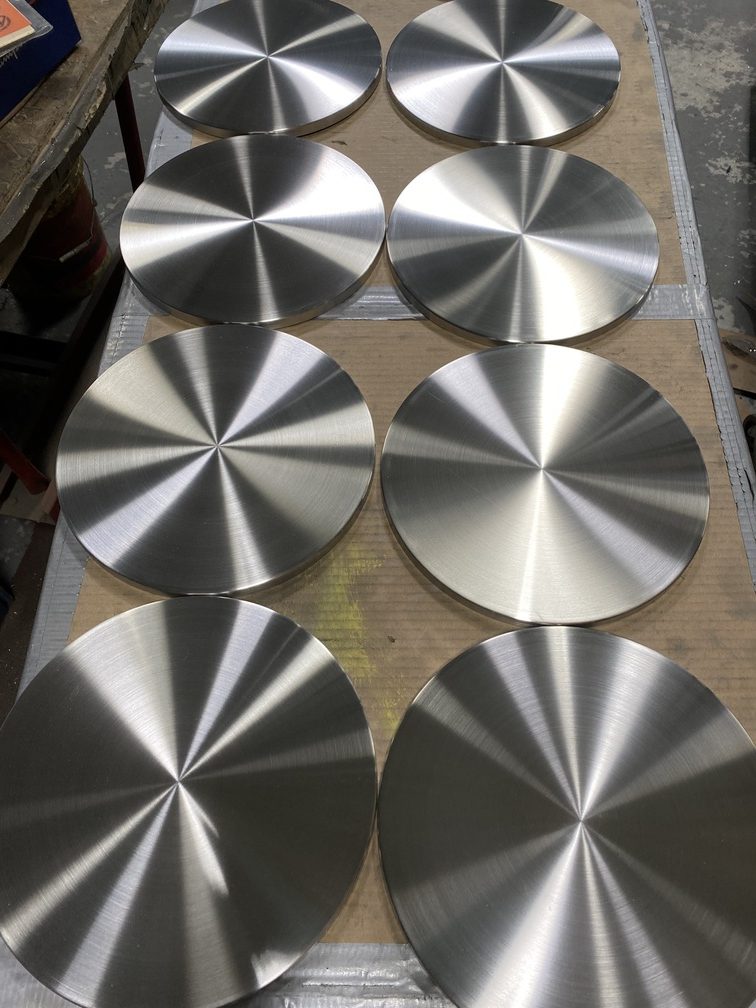

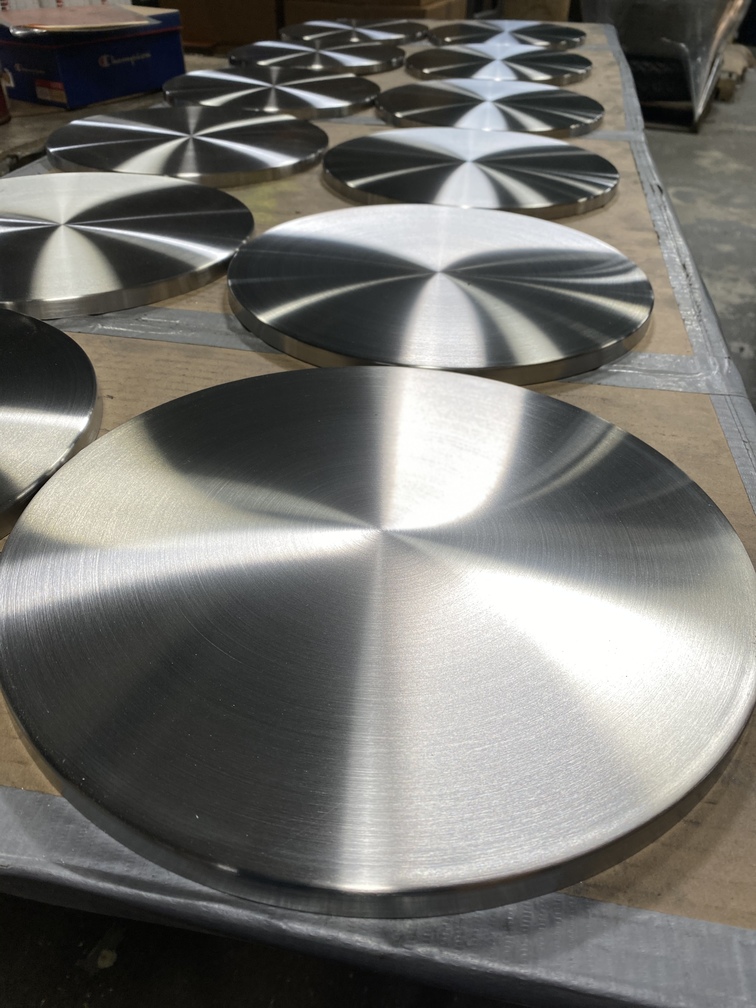

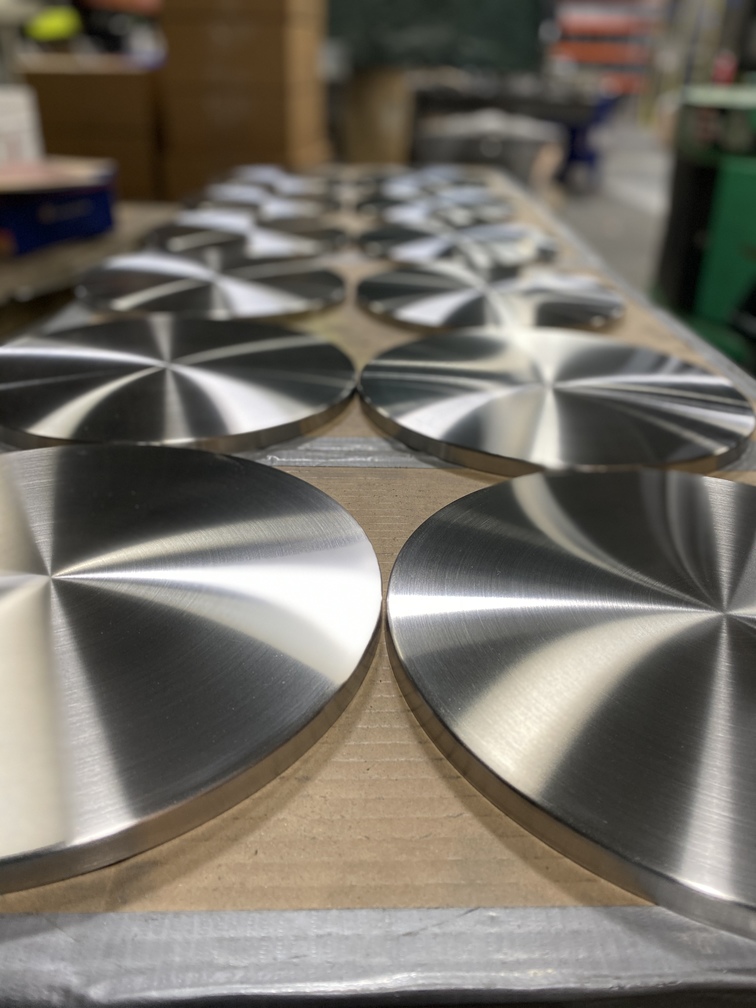

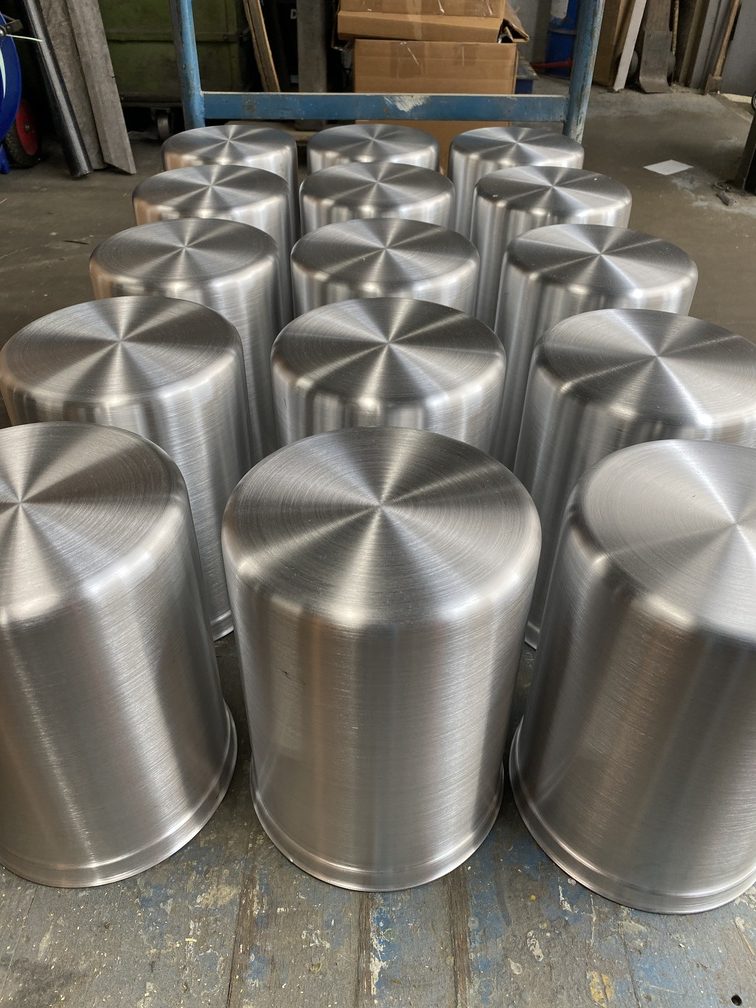

Aluminum is the most versatile metal for spinning. Almost any shape can be made. We have vast experience in spinning many type and alloys of aluminum; 1100 series, 5052, 3003, and 6061 are among the most common. Aluminum offer great flexibility is gauges also. We can make spinnings from .020 thick all the way to .156 thick. Certain types of aluminum can also be heat treated to different hardnesses. This is very useful when strength is needed and the shape prohibits the use of other materials.

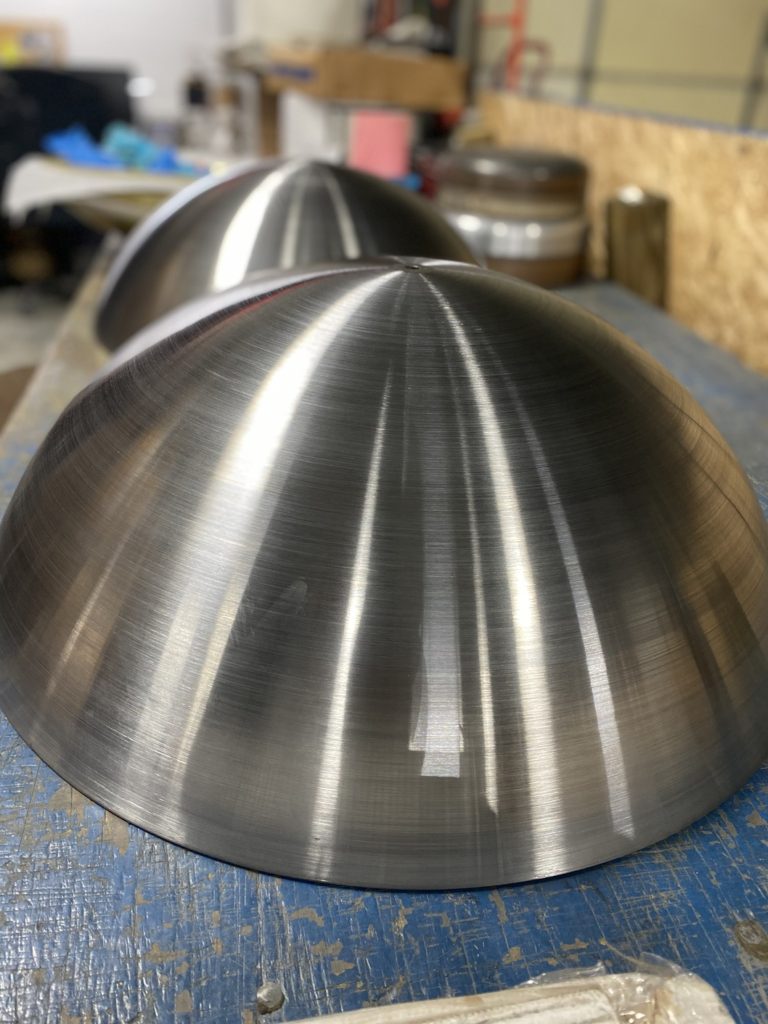

American Metal Spinning has many techniques to make just about any shape possible; whether it is a deep spun part, a cone shape, a large dish shape, hemispheres or shapes that return on themselves.

Some of the items that we are currently manufacturing include commercial lighting fixtures, commercial cookware, close tolerance shields and covers for the power industry, high performance car parts, duct and ventilation venturies. As you can see, aluminum spinnings can be incorporated into most designs. Aluminum is lightweight, anodizes well, has great weldibility. Aluminum is a cost effective way to produce any metal spinnings you may require. Give us a call and we will gladly discuss your designs and see if aluminum is the right material for your next job.

Aluminum is the most versatile metal for spinning. Almost any shape can be made. We have vast experience in spinning many type and alloys of aluminum; 1100 series, 5052, 3003, and 6061 are among the most common. Aluminum offer great flexibility is gauges also. We can make spinnings from .020 thick all the way to .156 thick. Certain types of aluminum can also be heat treated to different hardnesses. This is very useful when strength is needed and the shape prohibits the use of other materials.

American Metal Spinning has many techniques to make just about any shape possible; whether it is a deep spun part, a cone shape, a large dish shape, hemispheres or shapes that return on themselves.

Some of the items that we are currently manufacturing include commercial lighting fixtures, commercial cookware, close tolerance shields and covers for the power industry, high performance car parts, duct and ventilation venturies. As you can see, aluminum spinnings can be incorporated into most designs. Aluminum is lightweight, anodizes well, has great weldibility. Aluminum is a cost effective way to produce any metal spinnings you may require. Give us a call and we will gladly discuss your designs and see if aluminum is the right material for your next job.

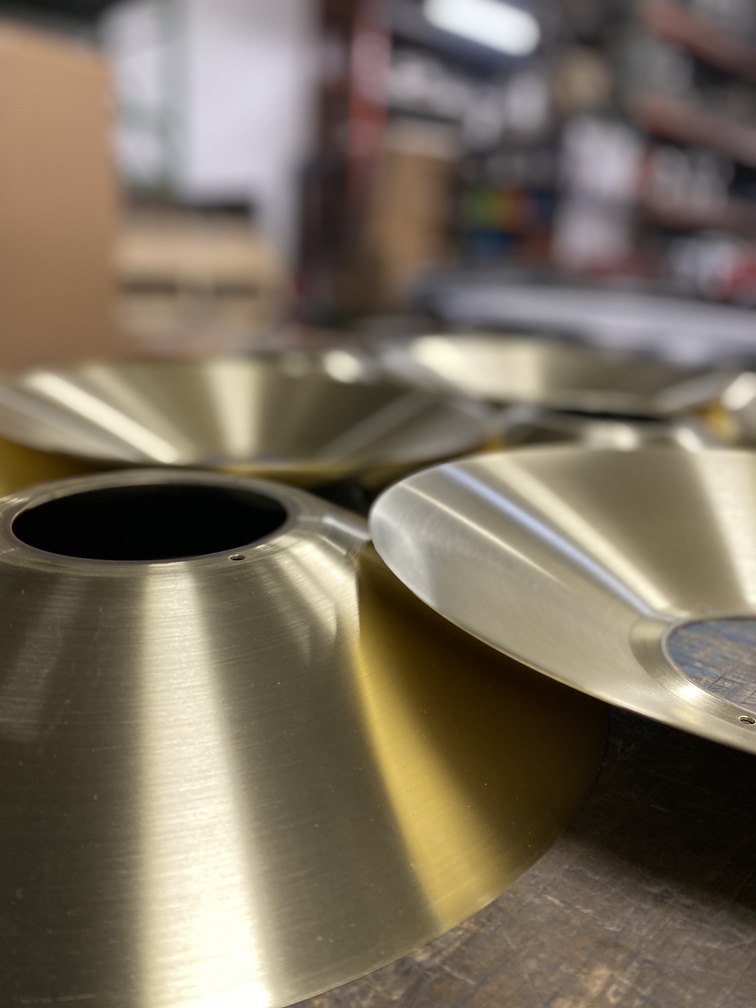

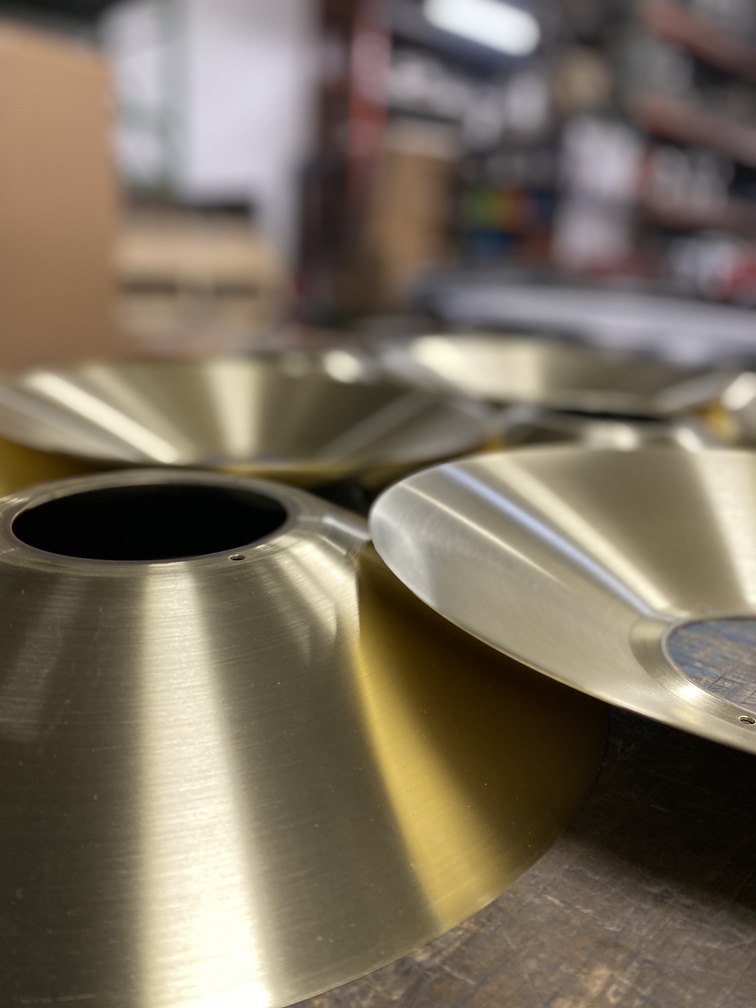

Brass Spinnings are beautiful. Most of our brass spinnings are for decorative purposes. We have made brass spinnings for large chandeliers, commercial light fixtures, canopies, lampshades, decorative finials, etc.. Most brass pieces we produce go on to be mirror polished. At this point in time, American Metal Spinning does not offer polishing. We do however, offer a beautiful satin finish. This finish can be left as is or can be polished until the desired effect is reached. We also have experience in the other families of brass: bronze, copper and muntz. While most brass is used for decorative parts, copper is used in the marine industry. We manufacture a number of couplings and reducers to fit your needs.

We have spun many gages of copper from a mere .010 thick all the way to a .125 thick. Spinning brass, bronze, and copper require certain techniques to achieve the desired shape. American Metal Spinning in well versed in these techniques; enabling us to provide you with the highest quality spinnings.

Brass Spinnings are beautiful. Most of our brass spinnings are for decorative purposes. We have made brass spinnings for large chandeliers, commercial light fixtures, canopies, lampshades, decorative finials, etc.. Most brass pieces we produce go on to be mirror polished. At this point in time, American Metal Spinning does not offer polishing. We do however, offer a beautiful satin finish. This finish can be left as is or can be polished until the desired effect is reached. We also have experience in the other families of brass: bronze, copper and muntz. While most brass is used for decorative parts, copper is used in the marine industry. We manufacture a number of couplings and reducers to fit your needs.

We have spun many gages of copper from a mere .010 thick all the way to a .125 thick. Spinning brass, bronze, and copper require certain techniques to achieve the desired shape. American Metal Spinning in well versed in these techniques; enabling us to provide you with the highest quality spinnings.

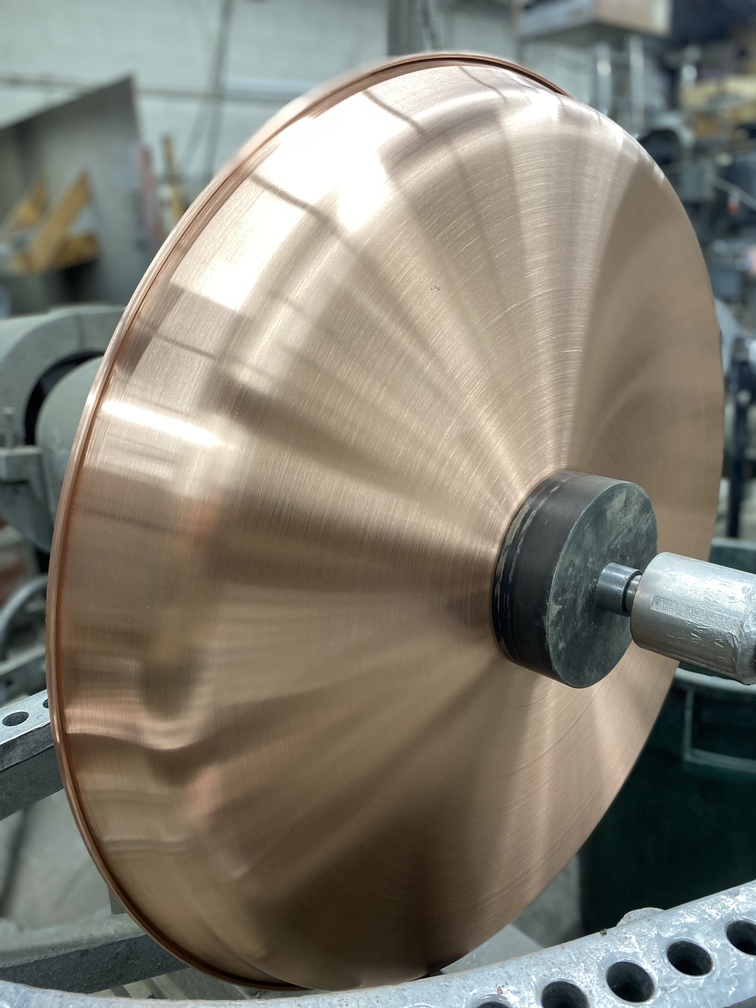

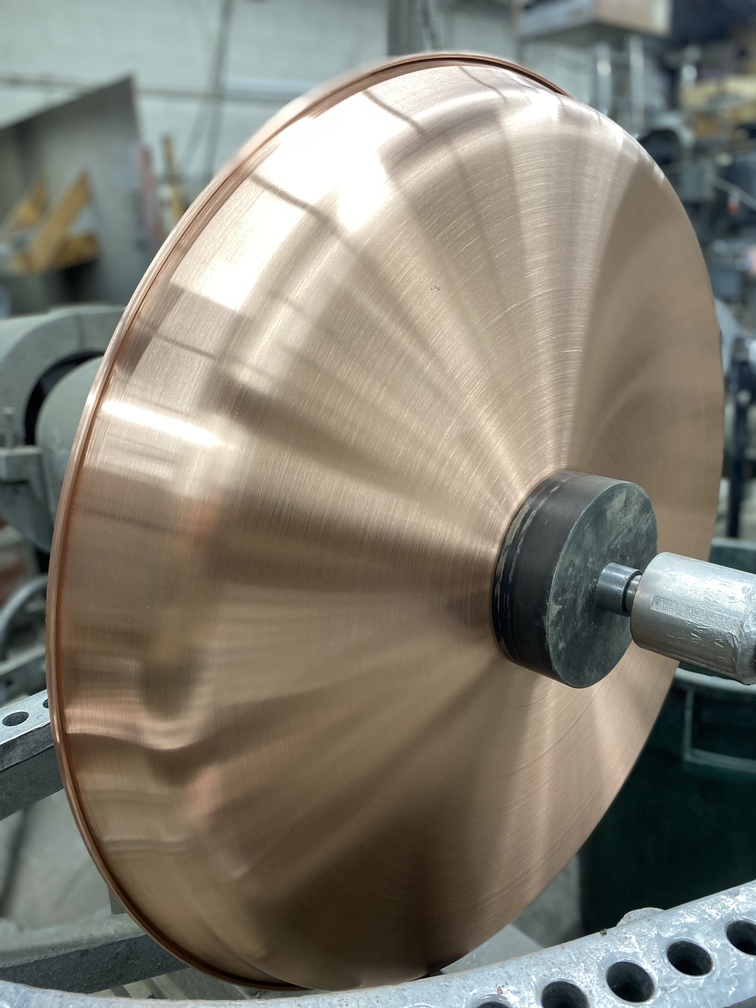

Most shapes are available in copper. Depending on the shape, one or more secondary operations may be needed to produce the final spinning. In our experience, copper has lent itself to two main fields, the first being the marine industry. We make a wide range of copper couplers and reducers. The second main category of copper spinnings is decorative lighting. Copper has the ability to patina very nicely. As mentioned, most shapes are attainable in copper spinnings. Give us a call and we’ll gladly discuss the possibility of any design with you.

Most shapes are available in copper. Depending on the shape, one or more secondary operations may be needed to produce the final spinning. In our experience, copper has lent itself to two main fields, the first being the marine industry. We make a wide range of copper couplers and reducers. The second main category of copper spinnings is decorative lighting. Copper has the ability to patina very nicely. As mentioned, most shapes are attainable in copper spinnings. Give us a call and we’ll gladly discuss the possibility of any design with you.

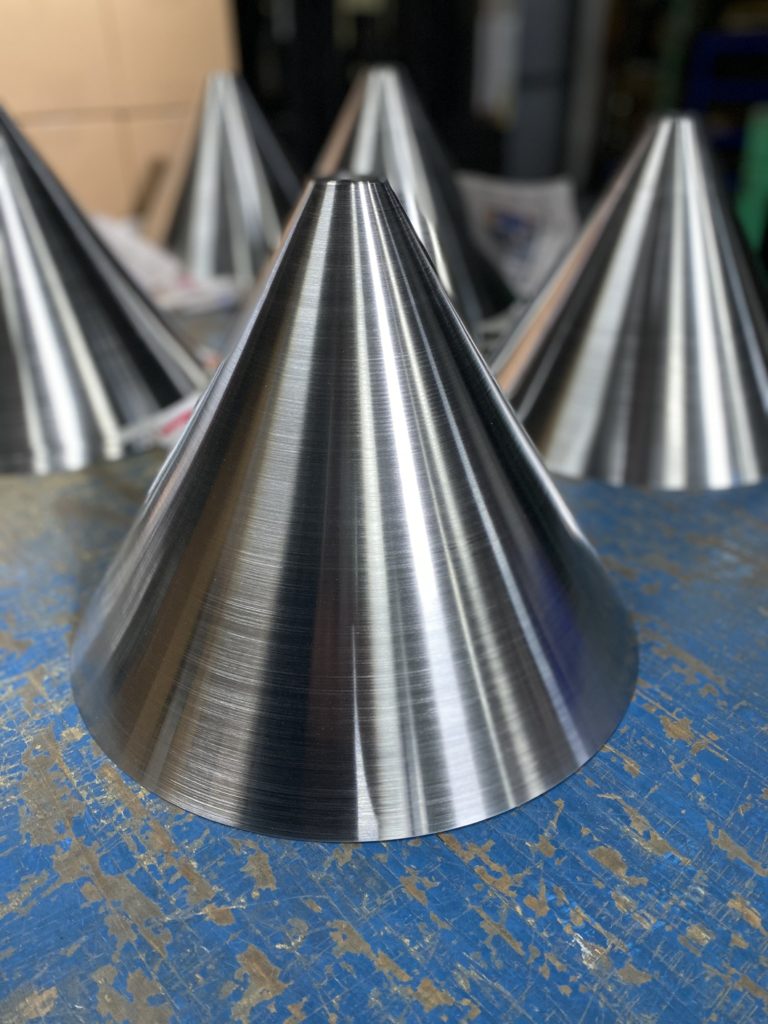

Steel is very spinnable. Most shapes are attainable in steel. We work in a wide range of gages and sizes with steel ranging from .020 thick all the way up to .125 thick, and even as large as 60″. Some of the parts that we have manufactured out of steel in the past have been: woks, baker bowls, funnels, cones, cans, pans, light fixtures, decorative bases, glass molds, fan covers, beauty trim rings, spheres, hemispheres, air cleaner covers, chandeliers and many others.

Steel is very spinnable. Most shapes are attainable in steel. We work in a wide range of gages and sizes with steel ranging from .020 thick all the way up to .125 thick, and even as large as 60″. Some of the parts that we have manufactured out of steel in the past have been: woks, baker bowls, funnels, cones, cans, pans, light fixtures, decorative bases, glass molds, fan covers, beauty trim rings, spheres, hemispheres, air cleaner covers, chandeliers and many others.

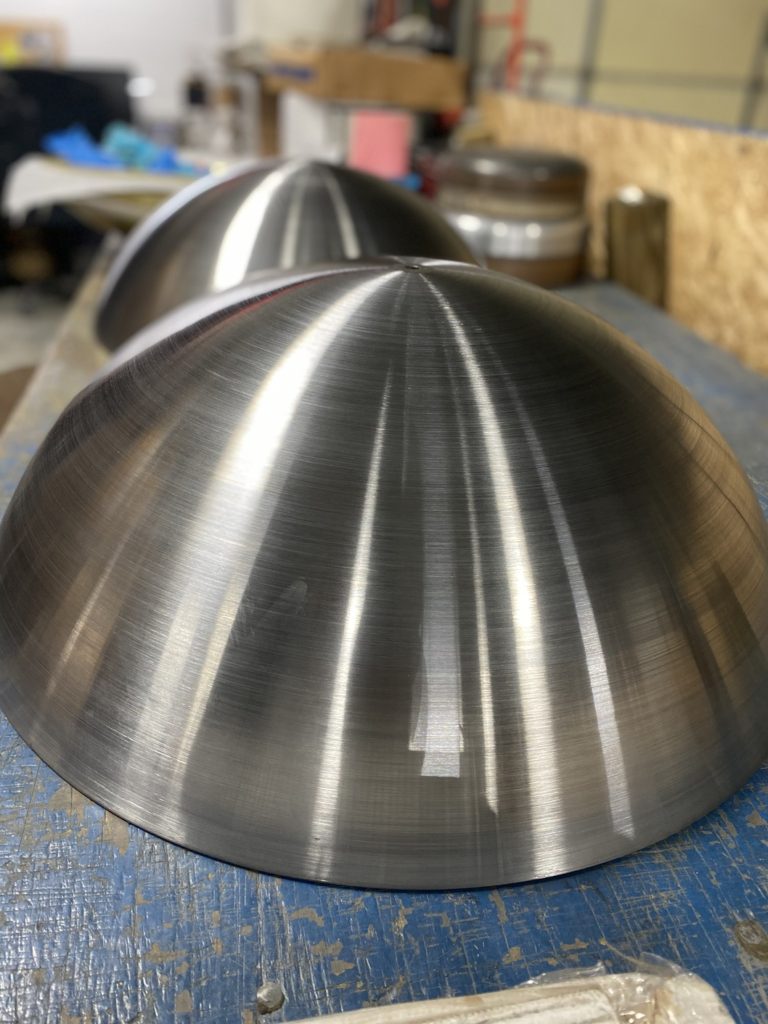

The inherent properties of stainless steel do not lend themselves well to spinning. Certain shapes are difficult to achieve in stainless steel, however, we have had great success with a number of shapes in the past. Items like glass molds (up to 56″), decorative bases, bowls, cups, lampshades, housings, pans, cones and rings. The most common gauge we spin in stainless steel is 18 gage. We have made spinnings from .019 thick to all tag way of to .125 thick. Many of the parts we make in stainless go on to be highly polished. We do not offer this service at this time, but we do offer a beautiful satin finish on all of our stainless steel spinnings. This attractive finish can be left as is or it can be polished to reach the desired effect. Spinning stainless steel is possible. However, it usually requires some special techniques and a multiple step spinning process to produce the desired shape. At times, this can become costly. If you require stainless steel for your design, don’t hesitate to call us and we will gladly discuss your next stainless project.

The inherent properties of stainless steel do not lend themselves well to spinning. Certain shapes are difficult to achieve in stainless steel, however, we have had great success with a number of shapes in the past. Items like glass molds (up to 56″), decorative bases, bowls, cups, lampshades, housings, pans, cones and rings. The most common gauge we spin in stainless steel is 18 gage. We have made spinnings from .019 thick to all tag way of to .125 thick. Many of the parts we make in stainless go on to be highly polished. We do not offer this service at this time, but we do offer a beautiful satin finish on all of our stainless steel spinnings. This attractive finish can be left as is or it can be polished to reach the desired effect. Spinning stainless steel is possible. However, it usually requires some special techniques and a multiple step spinning process to produce the desired shape. At times, this can become costly. If you require stainless steel for your design, don’t hesitate to call us and we will gladly discuss your next stainless project.

Aluminum is the most versatile metal for spinning. Almost any shape can be made. We have vast experience in spinning many type and alloys of aluminum; 1100 series, 5052, 3003, and 6061 are among the most common. Aluminum offer great flexibility is gauges also. We can make spinnings from .020 thick all the way to .156 thick. Certain types of aluminum can also be heat treated to different hardnesses. This is very useful when strength is needed and the shape prohibits the use of other materials.

American Metal Spinning has many techniques to make just about any shape possible; whether it is a deep spun part, a cone shape, a large dish shape, hemispheres or shapes that return on themselves.

Some of the items that we are currently manufacturing include commercial lighting fixtures, commercial cookware, close tolerance shields and covers for the power industry, high performance car parts, duct and ventilation venturies. As you can see, aluminum spinnings can be incorporated into most designs. Aluminum is lightweight, anodizes well, has great weldibility. Aluminum is a cost effective way to produce any metal spinnings you may require. Give us a call and we will gladly discuss your designs and see if aluminum is the right material for your next job.

Aluminum is the most versatile metal for spinning. Almost any shape can be made. We have vast experience in spinning many type and alloys of aluminum; 1100 series, 5052, 3003, and 6061 are among the most common. Aluminum offer great flexibility is gauges also. We can make spinnings from .020 thick all the way to .156 thick. Certain types of aluminum can also be heat treated to different hardnesses. This is very useful when strength is needed and the shape prohibits the use of other materials.

American Metal Spinning has many techniques to make just about any shape possible; whether it is a deep spun part, a cone shape, a large dish shape, hemispheres or shapes that return on themselves.

Some of the items that we are currently manufacturing include commercial lighting fixtures, commercial cookware, close tolerance shields and covers for the power industry, high performance car parts, duct and ventilation venturies. As you can see, aluminum spinnings can be incorporated into most designs. Aluminum is lightweight, anodizes well, has great weldibility. Aluminum is a cost effective way to produce any metal spinnings you may require. Give us a call and we will gladly discuss your designs and see if aluminum is the right material for your next job.

Brass Spinnings are beautiful. Most of our brass spinnings are for decorative purposes. We have made brass spinnings for large chandeliers, commercial light fixtures, canopies, lampshades, decorative finials, etc.. Most brass pieces we produce go on to be mirror polished. At this point in time, American Metal Spinning does not offer polishing. We do however, offer a beautiful satin finish. This finish can be left as is or can be polished until the desired effect is reached. We also have experience in the other families of brass: bronze, copper and muntz. While most brass is used for decorative parts, copper is used in the marine industry. We manufacture a number of couplings and reducers to fit your needs.

We have spun many gages of copper from a mere .010 thick all the way to a .125 thick. Spinning brass, bronze, and copper require certain techniques to achieve the desired shape. American Metal Spinning in well versed in these techniques; enabling us to provide you with the highest quality spinnings.

Brass Spinnings are beautiful. Most of our brass spinnings are for decorative purposes. We have made brass spinnings for large chandeliers, commercial light fixtures, canopies, lampshades, decorative finials, etc.. Most brass pieces we produce go on to be mirror polished. At this point in time, American Metal Spinning does not offer polishing. We do however, offer a beautiful satin finish. This finish can be left as is or can be polished until the desired effect is reached. We also have experience in the other families of brass: bronze, copper and muntz. While most brass is used for decorative parts, copper is used in the marine industry. We manufacture a number of couplings and reducers to fit your needs.

We have spun many gages of copper from a mere .010 thick all the way to a .125 thick. Spinning brass, bronze, and copper require certain techniques to achieve the desired shape. American Metal Spinning in well versed in these techniques; enabling us to provide you with the highest quality spinnings.

Most shapes are available in copper. Depending on the shape, one or more secondary operations may be needed to produce the final spinning. In our experience, copper has lent itself to two main fields, the first being the marine industry. We make a wide range of copper couplers and reducers. The second main category of copper spinnings is decorative lighting. Copper has the ability to patina very nicely. As mentioned, most shapes are attainable in copper spinnings. Give us a call and we’ll gladly discuss the possibility of any design with you.

Most shapes are available in copper. Depending on the shape, one or more secondary operations may be needed to produce the final spinning. In our experience, copper has lent itself to two main fields, the first being the marine industry. We make a wide range of copper couplers and reducers. The second main category of copper spinnings is decorative lighting. Copper has the ability to patina very nicely. As mentioned, most shapes are attainable in copper spinnings. Give us a call and we’ll gladly discuss the possibility of any design with you.

Steel is very spinnable. Most shapes are attainable in steel. We work in a wide range of gages and sizes with steel ranging from .020 thick all the way up to .125 thick, and even as large as 60″. Some of the parts that we have manufactured out of steel in the past have been: woks, baker bowls, funnels, cones, cans, pans, light fixtures, decorative bases, glass molds, fan covers, beauty trim rings, spheres, hemispheres, air cleaner covers, chandeliers and many others.

Steel is very spinnable. Most shapes are attainable in steel. We work in a wide range of gages and sizes with steel ranging from .020 thick all the way up to .125 thick, and even as large as 60″. Some of the parts that we have manufactured out of steel in the past have been: woks, baker bowls, funnels, cones, cans, pans, light fixtures, decorative bases, glass molds, fan covers, beauty trim rings, spheres, hemispheres, air cleaner covers, chandeliers and many others.

The inherent properties of stainless steel do not lend themselves well to spinning. Certain shapes are difficult to achieve in stainless steel, however, we have had great success with a number of shapes in the past. Items like glass molds (up to 56″), decorative bases, bowls, cups, lampshades, housings, pans, cones and rings. The most common gauge we spin in stainless steel is 18 gage. We have made spinnings from .019 thick to all tag way of to .125 thick. Many of the parts we make in stainless go on to be highly polished. We do not offer this service at this time, but we do offer a beautiful satin finish on all of our stainless steel spinnings. This attractive finish can be left as is or it can be polished to reach the desired effect. Spinning stainless steel is possible. However, it usually requires some special techniques and a multiple step spinning process to produce the desired shape. At times, this can become costly. If you require stainless steel for your design, don’t hesitate to call us and we will gladly discuss your next stainless project.

The inherent properties of stainless steel do not lend themselves well to spinning. Certain shapes are difficult to achieve in stainless steel, however, we have had great success with a number of shapes in the past. Items like glass molds (up to 56″), decorative bases, bowls, cups, lampshades, housings, pans, cones and rings. The most common gauge we spin in stainless steel is 18 gage. We have made spinnings from .019 thick to all tag way of to .125 thick. Many of the parts we make in stainless go on to be highly polished. We do not offer this service at this time, but we do offer a beautiful satin finish on all of our stainless steel spinnings. This attractive finish can be left as is or it can be polished to reach the desired effect. Spinning stainless steel is possible. However, it usually requires some special techniques and a multiple step spinning process to produce the desired shape. At times, this can become costly. If you require stainless steel for your design, don’t hesitate to call us and we will gladly discuss your next stainless project.